Product introduction

More than the sea fort microporous machine can be used for printing of bag making machine, square bottom valve bag making machine, laminating machine, sealing machine.

Microporous are widely used in the weaving industry. In industrial packaging filling valve pocket powder spray ash, powder leakage can be perfectly solved, the loading process is also more in line with the requirements of environmental protection; And shall not affect the printed page aesthetic and small bag body tension damage good moistureproof performance advantages. Between bag and woven bag lined with breathable, sealed bag of multilayer middle breathable, can use high density of pores is resolved. Many mining application solutions for customers, to inquire.

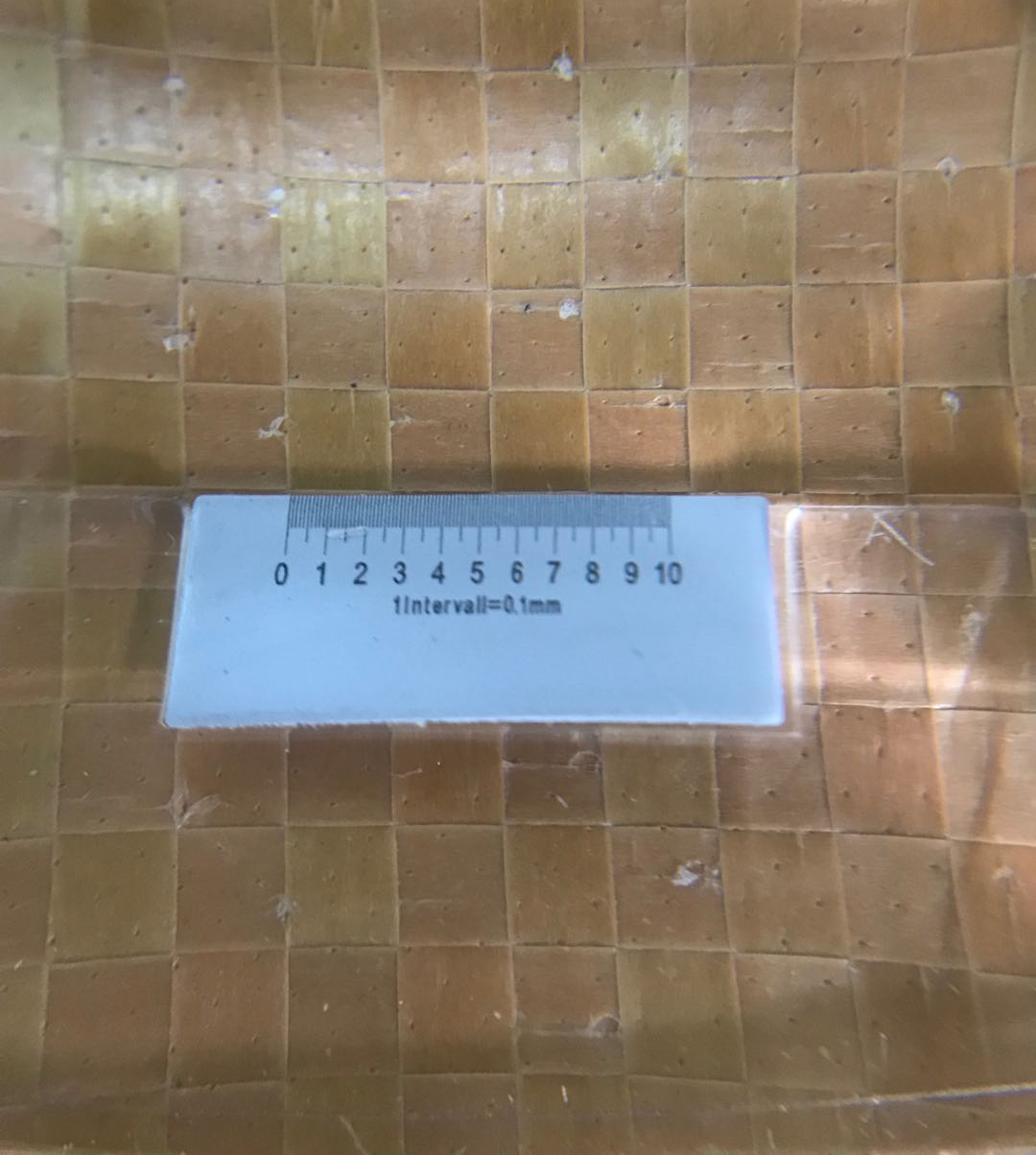

According to industry demand needle hole 64 hole / cm² squared, 81 hole/ cm² squared, coated with high 1.0 mm or 1.5 mm needle woven bag, three composite and multi-layer bag needle high 1.5 mm or 2.0 mm. 100% imported from Germany steel needle, needle of a complete set of ring is provided by strategic partner European companies and joint venture process make needlepoint roughness 0.05 mm or less, uniformity through 0.10 mm or less.

Product application:

Laminating machine, bag making machine -- - (graphic equipment)

Sealing machine, printing machine --- (Another poll)

Technical parameters:

|

Device name |

Micro needle punching machine |

|

Equipment model |

MP470 |

|

Piercings maximum width |

540mm(custom) |

|

Needle set width |

8135、145mm |

|

Piercings density |

64 hole /cm² 81 hole /cm² |

|

The needle diameter |

0.62mm |

|

Pinpoint smoothness |

≤0.05mm |

|

Piercings evenness |

≤0.10mm |

|

The depth of the trimming |

0.33mm/ circle 0.055mm/ engraved |

|

In her work |

0-200m/min |

|

The power supply |

380v/50hz |

|

The motor power |

5.5kw |

|

Overall dimensions |

2100×1850×1400mm |

|

The weight of the |

600kg |

|

note |

The bag body ventilation quantity |

Configuration list:

|

Steel needle |

Imported from Germany |

|

airbag |

Condi teck |

|

Rubber roller |

Φ 200mm |

|

Thick layer of induction |

Automatic needle back protection |

|

Quick release function |

Facilitate the needle set maintenance replacement |

|

Security guard |

And safe organic glass cover, convenient for observation |

Effect of punch

Germany imported steel needle

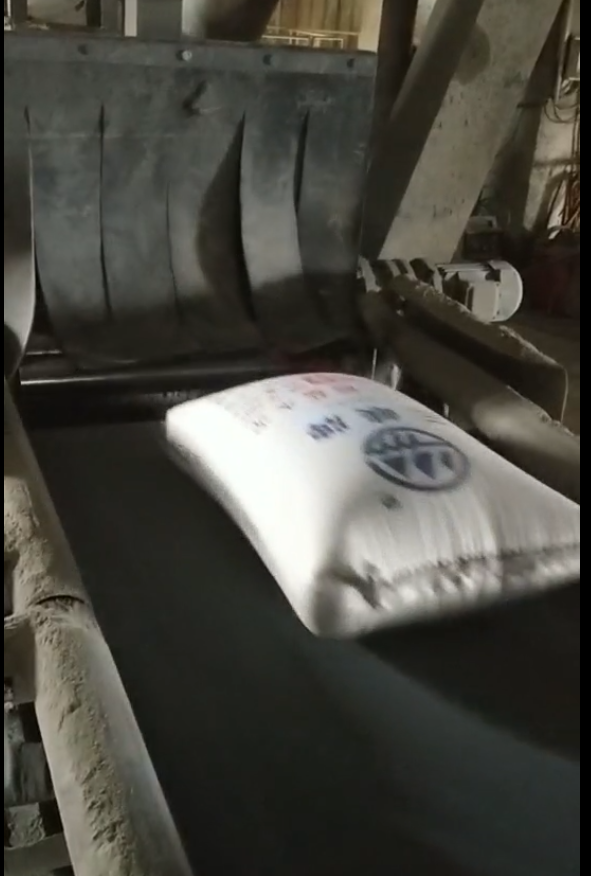

Not playing microporous bagged cement loading

Not dozen microporous bagged cement unloading

Hito Top Microporous machine made by cement bag, there would be no powder filling the powder leakage

Print This Page

Print This Page Bookmark This Page

Bookmark This Page Send Email

Send Email

Message

workday:7:30-17:00

Online Message